Diamond Rough to Polish in Surat, India – Reeva Rare

Diamond Rough to Polish in Surat India – Reeva Rare

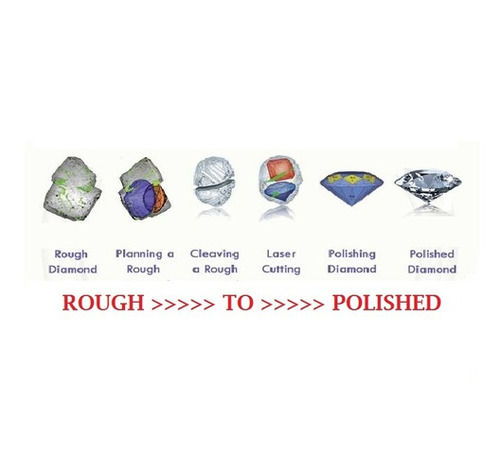

Diamond rough to polish in Surat India represents one of the most advanced and respected diamond transformation processes in the world. At Reeva Rare, every stone begins as a natural rough crystal and passes through carefully controlled stages before becoming a brilliant polished diamond. Surat leads the global diamond industry, and Reeva Rare continues that tradition through precision technology and expert craftsmanship.

Diamond Rough to Polish in Surat India – Selection and Planning

The journey of diamond rough to polish in Surat India starts with detailed grading and planning. Specialists at Reeva Rare examine each rough diamond under magnification and 3D mapping systems. They study inclusions, grain lines, and crystal orientation to determine the most effective cutting plan. This stage protects carat weight while maximizing brilliance and value.

After finalizing the cutting strategy, planners mark the stone using laser precision. Clear guidelines ensure accurate shaping and minimal material loss.

Cutting and Shaping in Diamond Rough to Polish in Surat India

During the next phase, artisans divide the rough stone through laser sawing or cleaving. Each movement follows the internal structure of the crystal. Then shaping begins. Through bruting and blocking, the diamond forms into round, oval, cushion, emerald, or other desired cuts.

Symmetry plays a critical role at this stage. Because proper proportion affects light reflection, expert control ensures balanced brilliance.

Faceting, Polishing, and Final Inspection

Faceting reveals the diamond’s sparkle. Craftsmen polish the main facets first and then complete the brillianteering stage to refine shine and alignment. This process demands patience and precision.

After polishing, quality inspectors review symmetry, surface finish, and proportion. The diamond undergoes ultrasonic cleaning before grading for cut, color, clarity, and carat weight.

Through every stage of diamond rough to polish in Surat India, Reeva Rare maintains strict standards, combining traditional artistry with modern innovation. The result is a polished diamond that reflects exceptional brilliance, structural integrity, and global quality excellence.